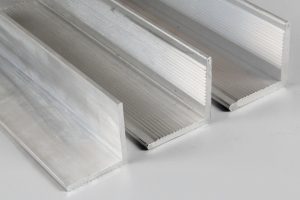

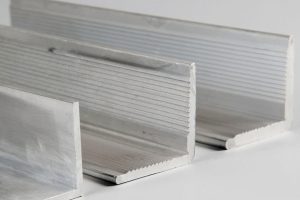

PV Frame (AA6063)

PV Frame (AA6063)

Features:

- Material Grade: AA6063 T5 (AA6060, AA6061, AA6082 available upon request)

- Dimensions: 40×40 mm / 35×35 mm

- Frame Length: 6 meters or customized based on your drawing

- Surface Treatment: Mill Finish

- Color: Aluminum Natural

- Delivery Format: In un-cut profiles / As pre-assembled units

- Services: Extrusion, Cutting, Punching, Drilling, Welding, Assembly, CNC Machining

- Application: Solar Module (PV Module) Assembly

Production Facilities

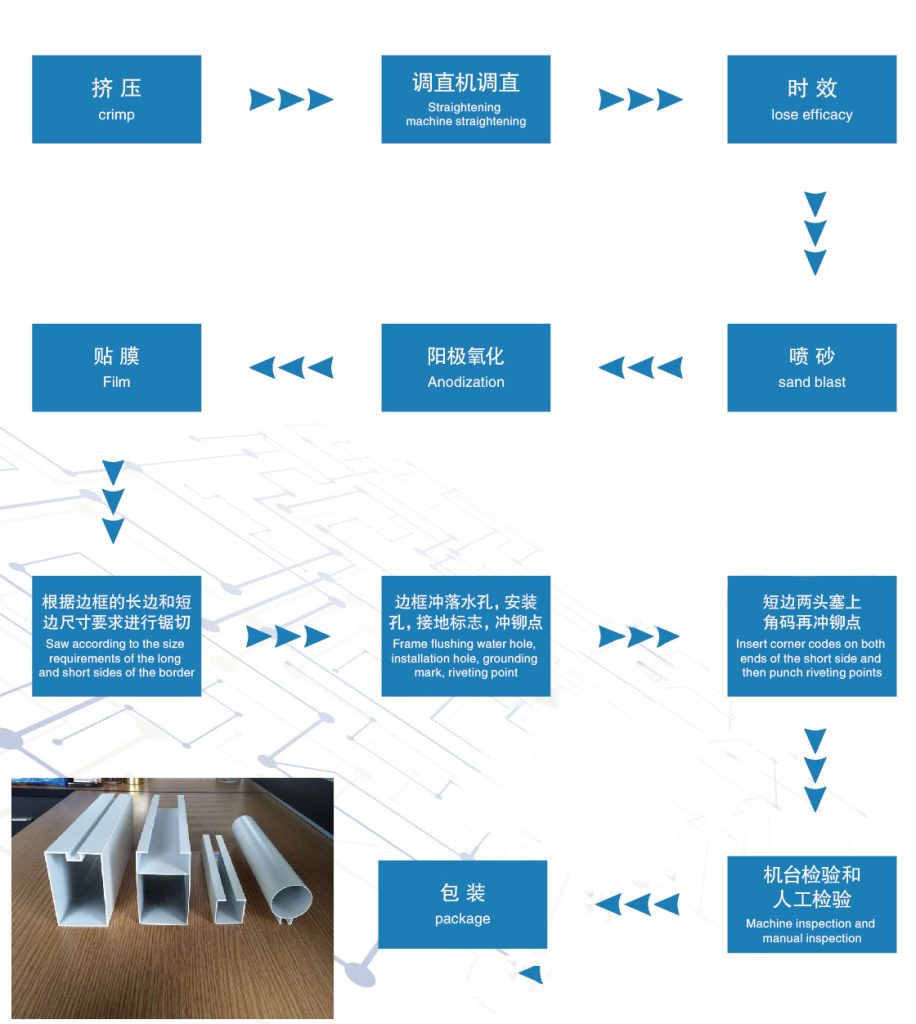

Production Process Flowchart

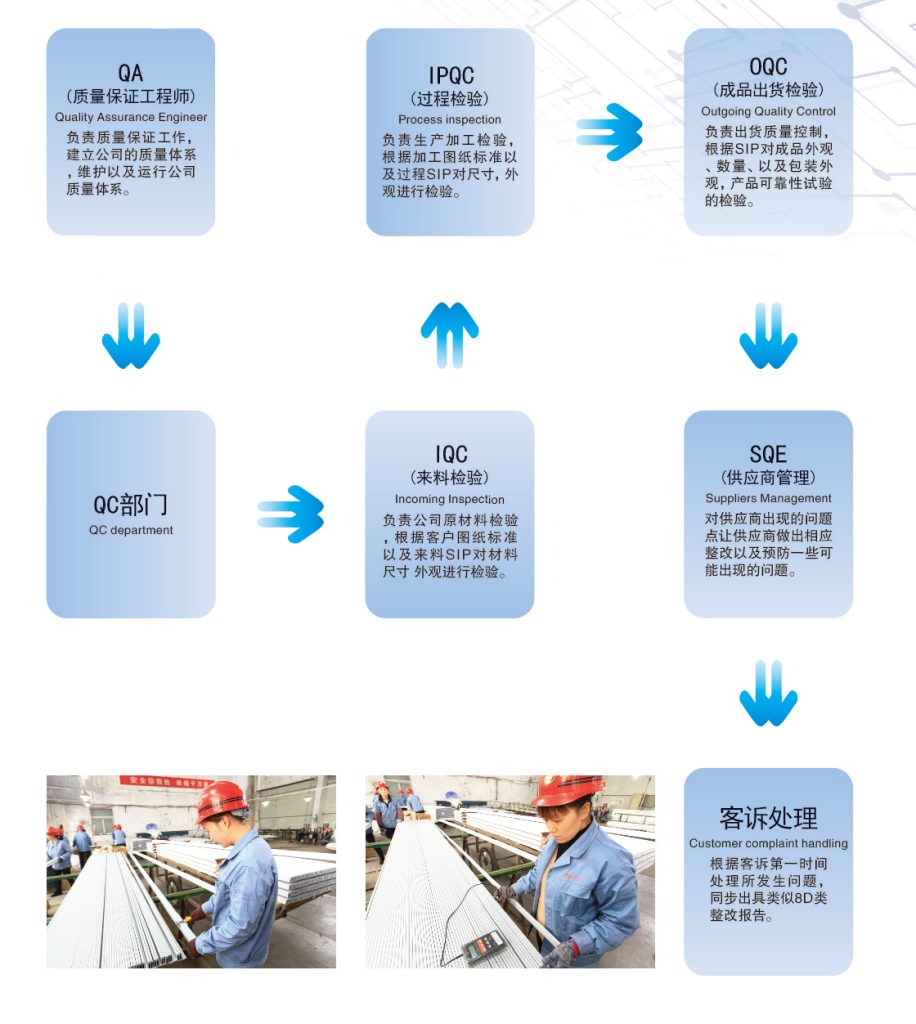

Quality Control (QC) Process

Technical Datasheet

Swipe right to view more data

| Product Details | |

|---|---|

| Item | Aluminum Solar Frame |

| Series | 6000 Series Aluminum Alloy (e.g., 6063, 6005, 6061) |

| Temper | T4, T5, T6 |

| Length | 3-6 meters, or customized based on client requirements |

| Shape | Round, Square, Flat, Hollow, Oval, Triangle, U-profile, L-profile, T-profile, Custom Shapes Available |

| Thickness | General profile thickness: 0.7 – 5.0mm |

| Processing | CNC Machining, Drilling, Milling, Cutting, Bending, Tapping, Welding, Assembly, Punching |

| Cross-section Dimensions | 30mm*35mm, 35mm*35mm, 35mm*40mm, 30mm*46mm, 35mm*45mm, 35mm*50mm, etc. |

Solar Frame Types

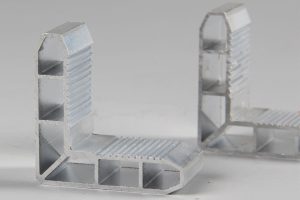

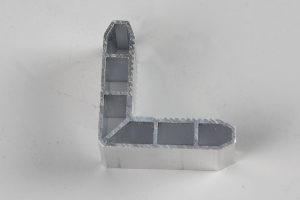

(1) 90°-Angle : fix with screws

(2) 45° -Angle : fix with Corner

Anodizing

Swipe right to view more data

| Anodizing Quality | ||||

|---|---|---|---|---|

| Grade | Corrosion Resistance | Abrasive Resistance | ||

| CASS Test | Alkaline | Sandtrial Abrasion | ||

| Hours Scroll right for more info | Grade Scroll right for more info | Dropping Scroll right for more info | coefficientf,g/um Scroll right for more info | |

| AA10 | 16 | >=9 | >=50 | >=300 |

| AA15 | 32 | >=9 | >=75 | >=300 |

| AA20 | 56 | >=9 | >=100 | >=300 |

| AA25 | 72 | >=9 | >=125 | >=300 |